You

must manually change the Standing Order

Status of the INV component on the standing order product to "Available"

before running this process. For more information, please see Defining

Standing Order Product Components.

You

must manually change the Standing Order

Status of the INV component on the standing order product to "Available"

before running this process. For more information, please see Defining

Standing Order Product Components.The purpose of this batch process report is to add new components for customers who have current "active" standing-order product orders. When a component product for a standing order product becomes available, run this process to create the detail line in each standing order to represent the product that is now available for shipping.

You

must manually change the Standing Order

Status of the INV component on the standing order product to "Available"

before running this process. For more information, please see Defining

Standing Order Product Components.

You

must manually change the Standing Order

Status of the INV component on the standing order product to "Available"

before running this process. For more information, please see Defining

Standing Order Product Components.

Credit

Card functionality has not yet been implemented for this process. Payment

still has to be manually entered, no payment scheduling or automatic credit

card payments.

Credit

Card functionality has not yet been implemented for this process. Payment

still has to be manually entered, no payment scheduling or automatic credit

card payments.

Standing order processing creates a new order line as “Active” within the existing order with the actual product being shipped in the series. New order line gets pricing components only if original standing order line product has pricing_method_code=‘Component’, or else the pricing remains with the original order. Most of the necessary information to create this order line comes from this existing order. Remaining information will be fetched from product setup table and parameters.

It

is recommended that you run this process whenever a new component becomes

available. INV900 will only pick up components if the Standing

Order Status of the component is "Available" and the

Standing Order Ship Date is

null. For more information, please see Defining

Inventoried Product Components.

It

is recommended that you run this process whenever a new component becomes

available. INV900 will only pick up components if the Standing

Order Status of the component is "Available" and the

Standing Order Ship Date is

null. For more information, please see Defining

Inventoried Product Components.

INV900

does NOT give free shipping on standing order lines. See Free

Shipping for more information.

INV900

does NOT give free shipping on standing order lines. See Free

Shipping for more information.

As

of 7.4.1SP1, the GetProrateFactor stored procedure called by INV900 has

been updated to allow for rounding up to 6 decimal points.

As

of 7.4.1SP1, the GetProrateFactor stored procedure called by INV900 has

been updated to allow for rounding up to 6 decimal points.

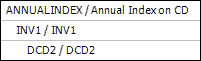

As

of 7.6.0, components of standing order product components will successfully

be added to orders by INV900. For example, if an INV product with a DCD

component is added as a component of a standing order product, the DCD

component will be added as a subline of the INV product subline in the

standing order product master line, as shown below.

As

of 7.6.0, components of standing order product components will successfully

be added to orders by INV900. For example, if an INV product with a DCD

component is added as a component of a standing order product, the DCD

component will be added as a subline of the INV product subline in the

standing order product master line, as shown below.

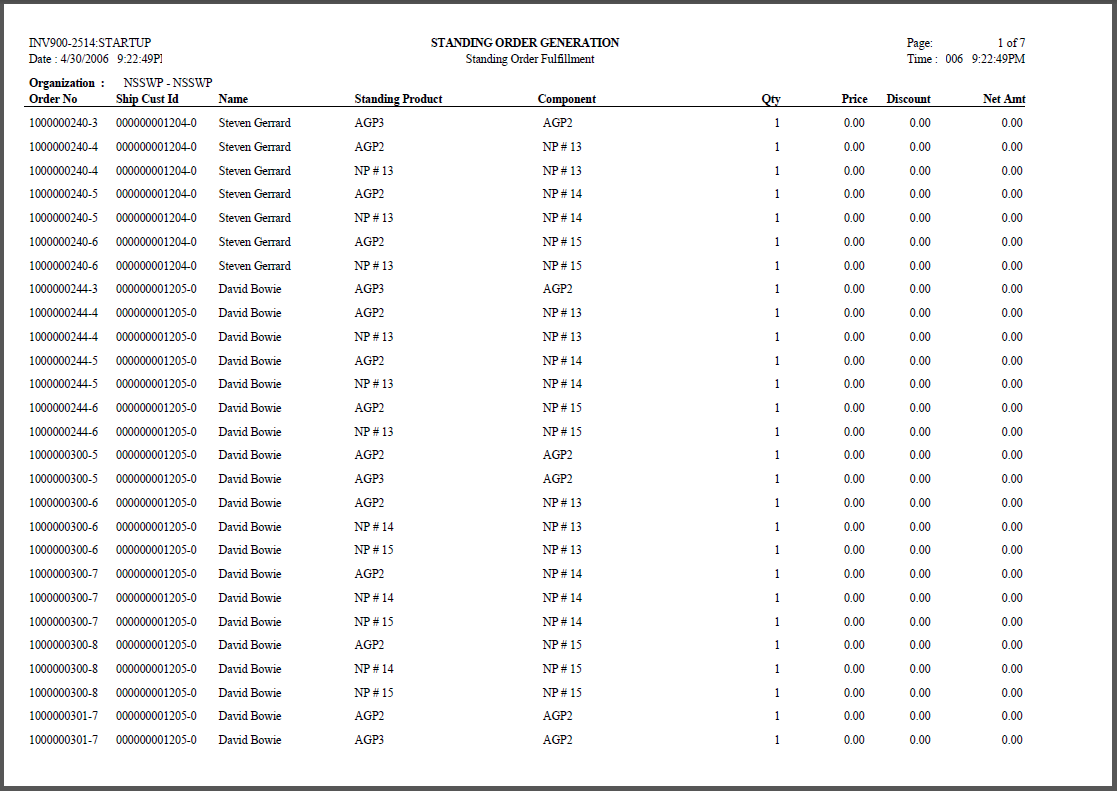

Parameter |

Description |

Required? |

|---|---|---|

Subtitle |

Alphanumeric. Enter a subtitle, which would appear below the report heading within the title of the report. |

No |

Run Mode |

· EDIT - no database updates takes place, the process only uses the parameters and query to select records for reporting. · PROD – the process updates the order tables, where necessary, and processes a report detailing the records selected and new order lines created. |

Yes |

Organization ID |

The Organization ID for which you want to run the report. |

Read-only |

Organization Unit |

The Organization Unit ID for which you want to run the report. |

Read-only |

Parent Product |

The standing Order Parent_ Product for which the new Component is being Fulfilled. |

No |

Product Code |

The Standing Order Product Code for which

the new component is being fulfilled. Standing_order_Status=‘Available’ and Standing_order_ship_date= 'NULL'. |

No |

Set Ship Date |

Select "Yes" if you want the system to set the Standing Order Ship Date on the Components screen. If running INV900 for all standing orders, this should be set to "Yes". If running for a subset of standing orders, this should be set to "No". |

Yes |

Ship Date for the Component |

Enter the date to be used as the Standing Order Ship Date for the standing order component in the standing order product setup. If this parameter is left blank, the Standing Order Ship Date for the standing order component will be set to the system date. |

No |

Ship Via Code for New Orders |

If entered, the process sets this Ship Via Code on the Shipping Information tab in Order Entry for the new order lines (Order_detail.SHIP_VIA_CODE).

If left blank, the process retains the Ship Via Code of the master order line. |

No |